Location

23 Shaban Street, Albion Park Rail

Looking to refresh your driveway, patio, or walkway? Stencil concrete is a practical and cost-effective solution to last your property. ICR Concrete Supplies is your one-stop shop for all your concrete needs.

Stencilled Concrete is a popular low-cost alternative to laying real stones, pavers, tiles or bricks. With a huge range of colour and pattern combinations available, this non-slip surface of stencilled concrete offers a versatile design to your property while providing an added layer of durability. Not only is it practical and cost-effective but it is almost maintenance-free.

Stencilled concrete exhibits realistic-looking grey “mortar joints” which are created by masking off plain grey concrete beneath using stencils. However, if you do not like the “mortar joints”, then another popular option is applying a base colour of choice and then stencilling over it.

Before the job begins, a base colour (If you do not want plain grey “mortar joints”), secondary colour, and pattern are all selected.

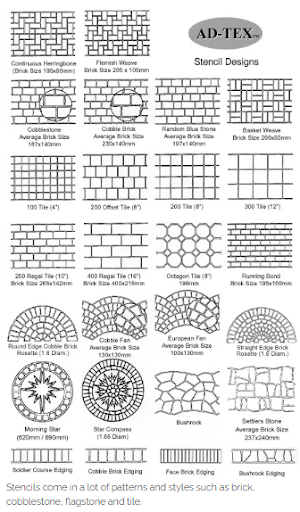

Manufactured from an Australian premium grade stencil board AD-TEX, stocked by ICR, stencil patterns are computer cut using state-of-the-art rotary die-cutting machinery providing you with a perfect pattern match from roll to roll.

Custom logos and unique feature designs can also be incorporated. Rolls of stencil can come in various patterns, including brick, cobblestone, flagstone, and tile.

To begin stencilling concrete, the standard procedure of pouring, screeding, floating, and edging the concrete should be followed. Once the surface is clear of excess bleed water, it should be steel-troweled or bull-floated entirely. Additional tools that can assist with this project include a clip-together telescopic handle, a walking trowel, and a cove trowel.

Since the strips are die-cut, it is crucial to align each stencil strip accurately, similar to aligning wallpaper, to ensure the pattern is connected seamlessly.

Here are some steps that you can follow on how you can stencil concrete correctly.

Measure the area where you plan to stencil concrete to determine the required length of your forms and the number of pieces needed to cover the width of the surface.

Before pouring the concrete, cut the stencils from the roll, allowing for quick placement once the concrete is formed.

Before installing the concrete surface, make sure to cover any existing flooring and structures and block off the area where it will be placed.

After pouring the concrete, use a screed and float to level it to the required height. If you want to speed up this process, you can use self-levelling concrete.

Using tape, mark the centre of the concrete surface. Make sure to locate the centre line by measuring from the edge of the concrete surface.

In this step, you may need to ask assistance from another person to ensure correct measurements. Have two people stand on opposite sides and stretch a piece of tape through the middle to mark a line from the centre of the surface to the edge.

Lay out the stencil strips starting from the centre and work towards the edges.

Use a trowel or stencil roller to adhere the stencil onto the concrete to form a raised pattern.

Tint the exposed concrete using a colour hardener by sprinkling it onto the exposed sections. Next, use a bull float to float the colour towards the form's borders. You may use a trowel to close the surface or employ a roller, wood, sponge or cork to create a decorative finish.

Follow the manufacturer's instructions as you may need to apply 2 coats.

Apply a release agent as per the manufacturer's instructions.

Once the concrete is adequately dry, remove the stencil to prevent the form from sticking to the surface. While doing so, expect to remove concrete chips and dust from the edges.

Flush the surface with water to remove larger pieces of concrete.

Remove the remaining small debris left on the concrete.

Following the guidelines provided by the manufacturer, apply two coats of sealer. The first layer, which should be lighter, must contain 15-20% acrylic, while the second layer, which should be heavier, should have 25-35% acrylic.

Our coloured concrete comes in 28 colours.

For new/fresh concrete you will need a dry shake colour hardener. A dry shake colour hardener is a powdered mixture of pigments, sand, cement and wetting agents, packaged in bags or pails. Not only will it give the new/fresh concrete area a decorative colour but it will also harden the surface and protect it against wear and abrasion.

For more product and application information

click here.

Concrete resurfacing is an effective method to renovate aged or existing concrete and restore its original appearance. When applying a concrete coating on top of the current surface, you can choose from a range of colour, texture, and pattern options. Wherever you need it, you can apply this decorative concrete restoration process to driveways, patios, pool decks, and even indoor floors.

If you are revitalising existing concrete, you will need a resurfacing compound, AD-Tex T5 spray-on. For more product and application information

click here.

If you do not want plain grey “mortar joints”, you would apply a base coat before laying the stencil.

Once decorative concrete or new concrete colours are finished, the best way to keep them looking great is to seal and protect their surface. At ICR Concrete Supplies, we provide premium-quality concrete sealers that effectively shield concrete surfaces from abrasion to ensure their longevity. With our concrete sealers, not only will your concrete surfaces acquire a pristine appearance, but you can also clean and maintain them without effort.

Ranging from clear, high-gloss & matt finishes, same-day application, coloured and an additive for slip resistance, ICR concrete sealers are specifically designed to offer a protective coating that preserves your concrete surfaces for a long time.

Stencilling your concrete is an excellent option to spruce up dull surfaces without spending too much. By following the right steps and using the right materials and tools, you can personalise your concrete area to your liking.

ICR Concrete Supplies offers an extensive range of products for stencilling concrete, such as concrete stencils, coloured concrete, concrete sealer, mesh, concrete tools, and other decorative concrete supplies.

Whether you're a DIY enthusiast or a professional contractor, ICR Concrete Supplies has your needs covered. We also provide helpful tips and advice to ensure that your stencilling project is done right the first time.

If you have any questions or are looking for something specific, please do not hesitate to

contact us for expert advice and guidance, our experienced staff will answer any questions you may have about our products and services.

ICR Concrete Supplies and Wollongong Waterproofing Supplies both operate in the Illawarra and stock large ranges of tools and products for both tradies and domestic D.I.Y projects.

Suppliers of concreting products and tools including pavement paint, concrete sealer, drainage, rendering tools, mesh and steel reinforcement.

Call For An Instant Quote.

Mon-Fri 6.30 am - 4.30 pm and Sat 7am - 12pm

Phone: 02 4257 1196

Or Email Us Here